Compact, robust and reliable, the Sanitary Diaphragm Pump is air operated, ideal for a range of industries from beverages to cosmetics.

Tapflo’s Sanitary Diaphragm Pump is available with our revolutionary Low Energy Air Pump (LEAP) technology which will reduce your operating costs and help your business to meet energy targets. LEAP could save your company up to 70% on energy as these pumps begin operating at a much lower starting pressure than standard AODs on the market (0.2 compared to 1.2).

A heating jacket is a great option when the pumped product tends to solidify at lower temperatures e.g. Chocolate or paraffin. When the pump has finished its duty and is left for some time without operation the product can solidify inside. This is when the heating jacket comes in. Before the next pump start-up, a heating medium like water or steam is into the heating system for a defined period of time to melt the product inside the pump. Only then can the pump be started again with no risk of damage.

NOTES: When using steam as the heating agent the flow must be from top to bottom (due to steam condensation). In the case of hot water or other liquid, it is the other way around. Do NOT exceed 2 Bar pressure in the jacket.

Tapflo’s Sanitary Diaphragm Pump is available with our revolutionary Low Energy Air Pump (LEAP) technology which will reduce your operating costs and help your business to meet energy targets. LEAP could save your company up to 70% on energy as these pumps begin operating at a much lower starting pressure than standard AODs on the market (0.2 compared to 1.2).

A heating jacket is a great option when the pumped product tends to solidify at lower temperatures e.g. Chocolate or paraffin. When the pump has finished its duty and is left for some time without operation the product can solidify inside. This is when the heating jacket comes in. Before the next pump start-up, a heating medium like water or steam is into the heating system for a defined period of time to melt the product inside the pump. Only then can the pump be started again with no risk of damage.

NOTES: When using steam as the heating agent the flow must be from top to bottom (due to steam condensation). In the case of hot water or other liquid, it is the other way around. Do NOT exceed 2 Bar pressure in the jacket.  Looking for more information about Sanitary Pumps, visit TS Pumps’ Sanitary Pump Guide today for more!

Looking for more information about Sanitary Pumps, visit TS Pumps’ Sanitary Pump Guide today for more! | Technical Information | |

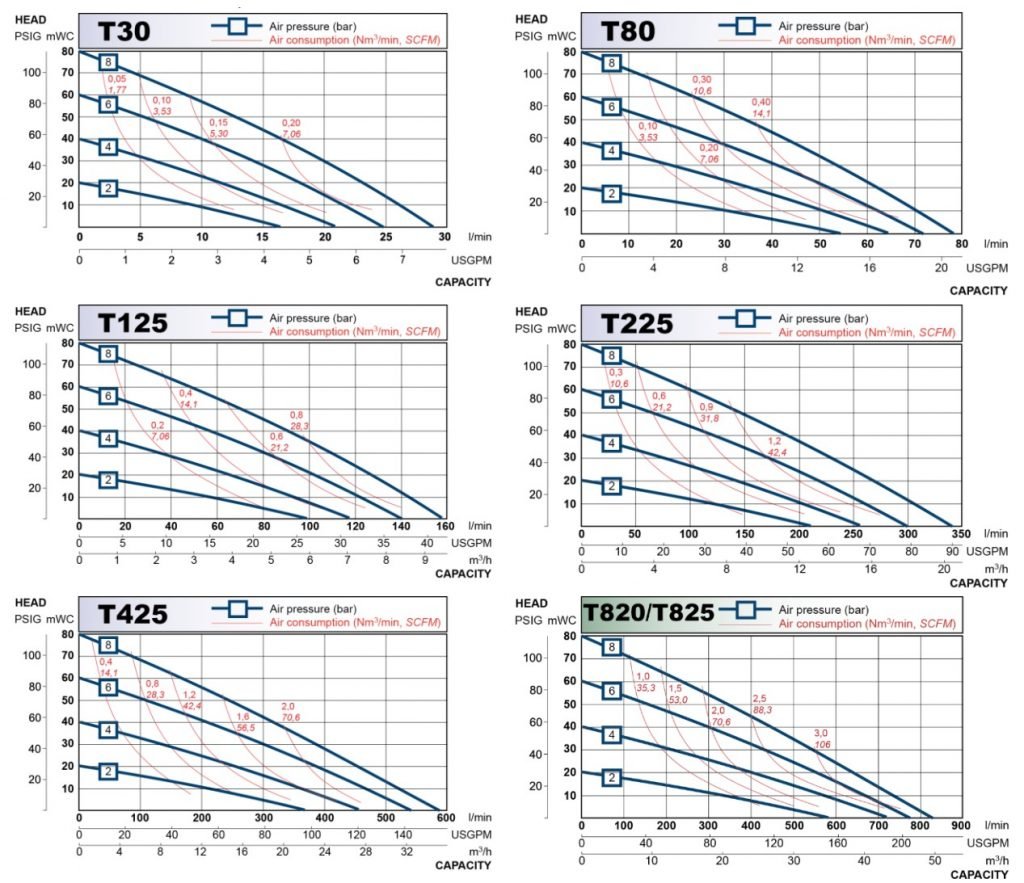

| Capacity | Up to 825l/min |

| Volume | Up to 4500ml – based on pumps fitted with EPDM Diaphragms |

| Materials | Stainless Steel AISI 316L. Extra fine surface finish to RA 0.8 as standard, or RA 0.5 upon request |

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

01928 333 400<br> [email protected]<br> [email protected]<br>

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Pump in need of repair? Call TS Pumps today on 01928 333 400

Pump in need of repair? Call TS Pumps today on 01928 333 400

Mon – Thurs 08:30 – 17:00 Friday 08:30 – 16:30

TS Pumps, 10 Cormorant Drive, Runcorn, Cheshire, WA7 4UD