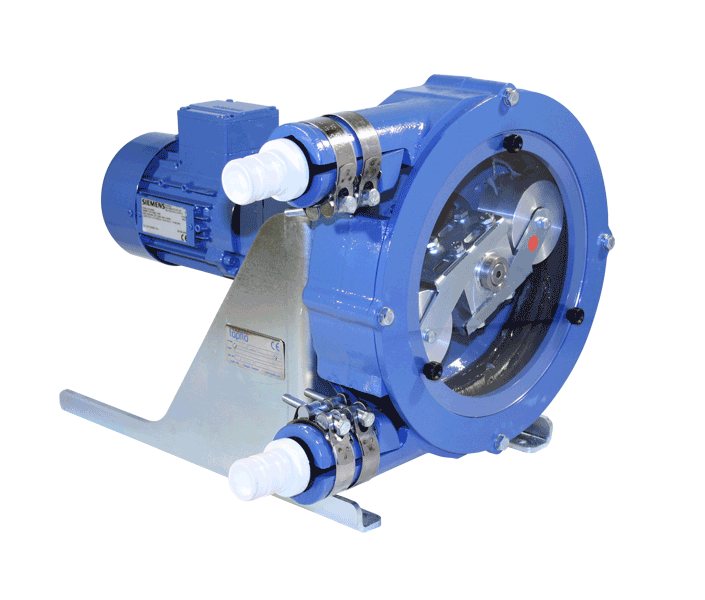

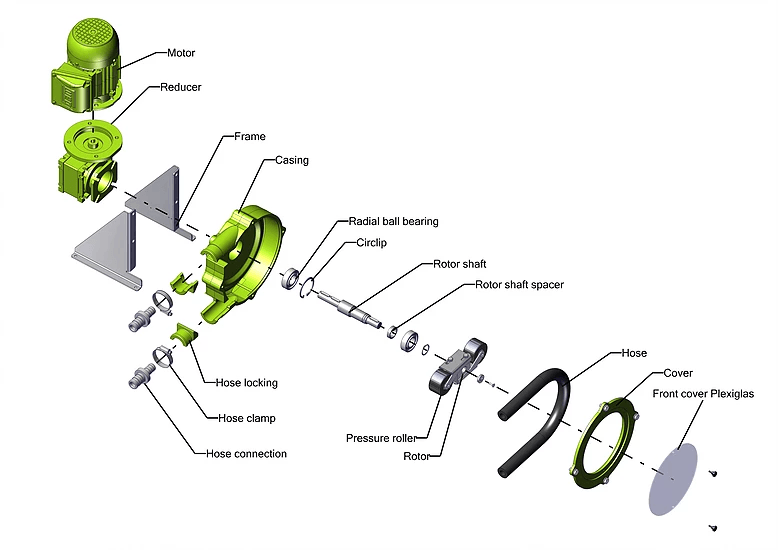

The PTL is the low-pressure option within our Peristaltic Pump range, it has been designed for low flow batching and metering applications that require accurate control.

| PTL Series | |

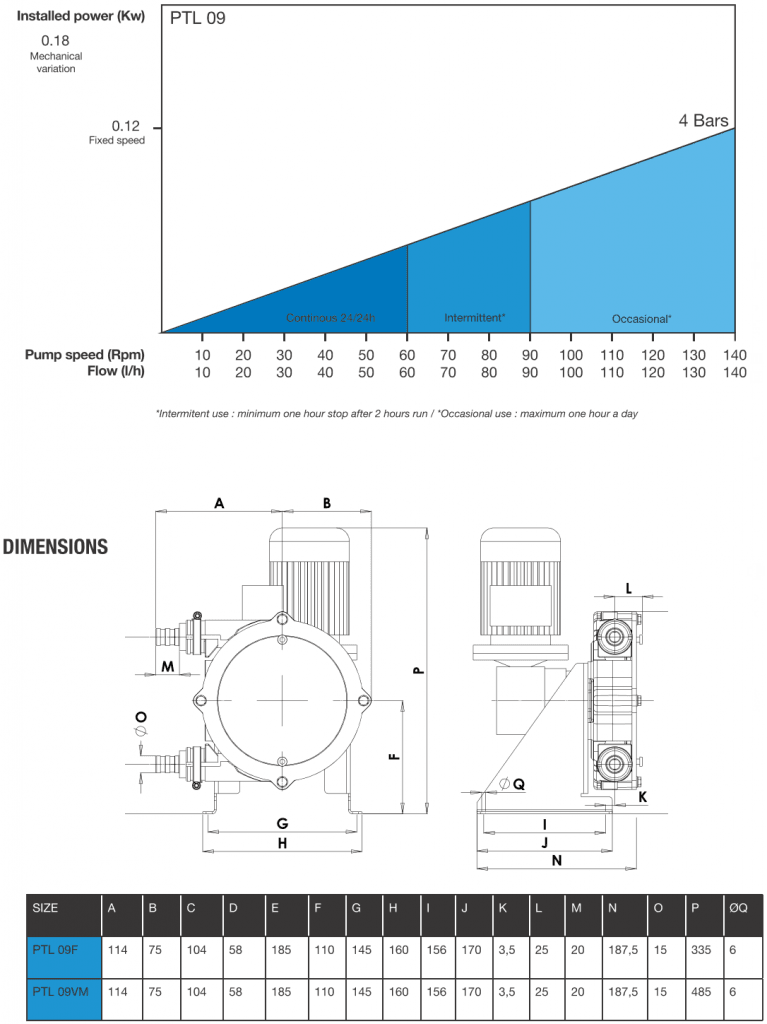

| Capacity | Up to 10 m³/hr |

| Accuracy | /- 0.5% |

| Viscosity | Up to 15’000 cPs |

| Fluid Temperature | Up to 135ºC |

| Differential Pressure | Up to 4 Bar |

| Max Solids Passage | Up to 9 mm |

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

01928 333 400<br> [email protected]<br> [email protected]<br>

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Pump in need of repair? Call TS Pumps today on 01928 333 400

Pump in need of repair? Call TS Pumps today on 01928 333 400

Mon – Thurs 08:30 – 17:00 Friday 08:30 – 16:30

TS Pumps, 10 Cormorant Drive, Runcorn, Cheshire, WA7 4UD