The Industrial Self-Priming Centrifugal Pump is versatile which means it can be used by industries including industrial, food, pharmaceutical and beverage. This pump is perfect for these industries due to the suction lift feature or its ability to pump highly aerated fluids.

| Drive Type | Electric |

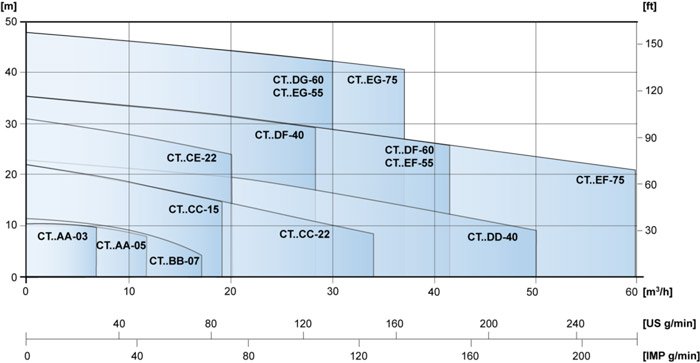

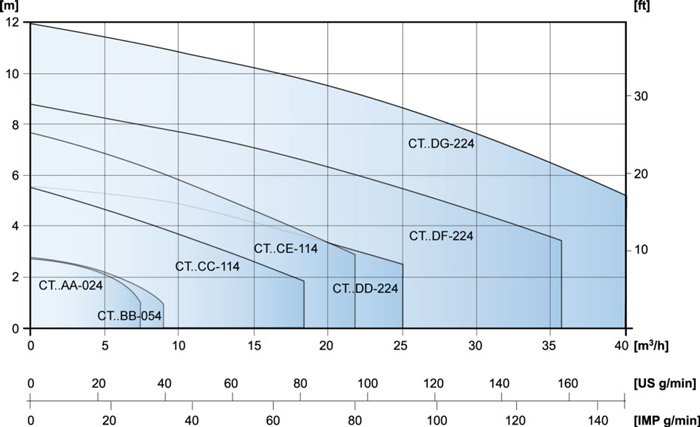

| Flow Rate | up to 58 m³/hr |

| Pressure | up to 40m |

| Material | Stainless Steel AISI 316L |

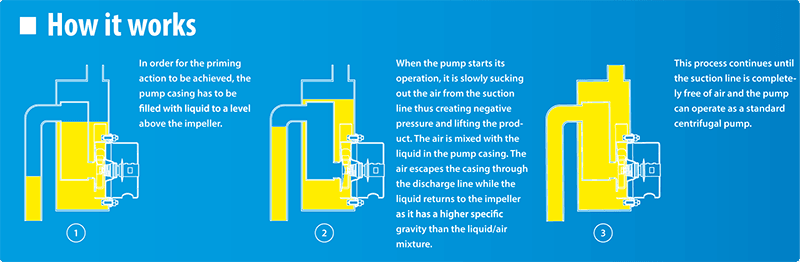

| Self-Priming | Yes |

| Solids Handling | up to 6mm |

| Viscosity | 0-200 cSt |

| Casing | Stainless Steel AISI 316L, Glass Blasted |

| Impeller | |

| Mechanical Seal | Single Ceramic / Graphite (Std.), SiC / SiC or SiC / Graphite, Optional with Lubrication or Flushing |

| O-Rings | EPDM (Std.), FKM, FEP / Silicon or NBR |

| Motor | IP55; IEC frame B34; Available with ATEX cat 2 or 3; Eex e or Eex d |

| Pressure Rating | 10 bar (PN10) |

| Temperature | Max 90°C |

| Viscosity | Max ~200 cSt |

| Particles | Max diameter is 6 mm (std open impeller); bigger if soft particles |

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

01928 333 400<br> [email protected]<br> [email protected]<br>

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Pump in need of repair? Call TS Pumps today on 01928 333 400

Pump in need of repair? Call TS Pumps today on 01928 333 400

Mon – Thurs 08:30 – 17:00 Friday 08:30 – 16:30

TS Pumps, 10 Cormorant Drive, Runcorn, Cheshire, WA7 4UD