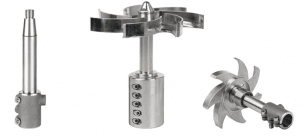

Pomac’s CPC Sanitary Centrifugal Pump is ideal for the food and pharmaceutical industries due to its outstanding cleaning ability and its sturdy design. They are simple to maintain and work efficiently which keeps maintenance costs down.

| CPC-IL | Stainless Steel Sanitary, designed with In-Line connections. Pump can be installed directly into the pipework. |

| CPC-WW | Stainless Steel for whey curds, designed with tangential outlet. Maximum operational speed of 1000rpm. |

| CPC-T | Stainless Steel Sanitary, designed with radial outlet. |

| CPC-ZA | Self-Priming, not EHEDG certified but sanitary in construction. ATEX rated. |

| Technical Information | |

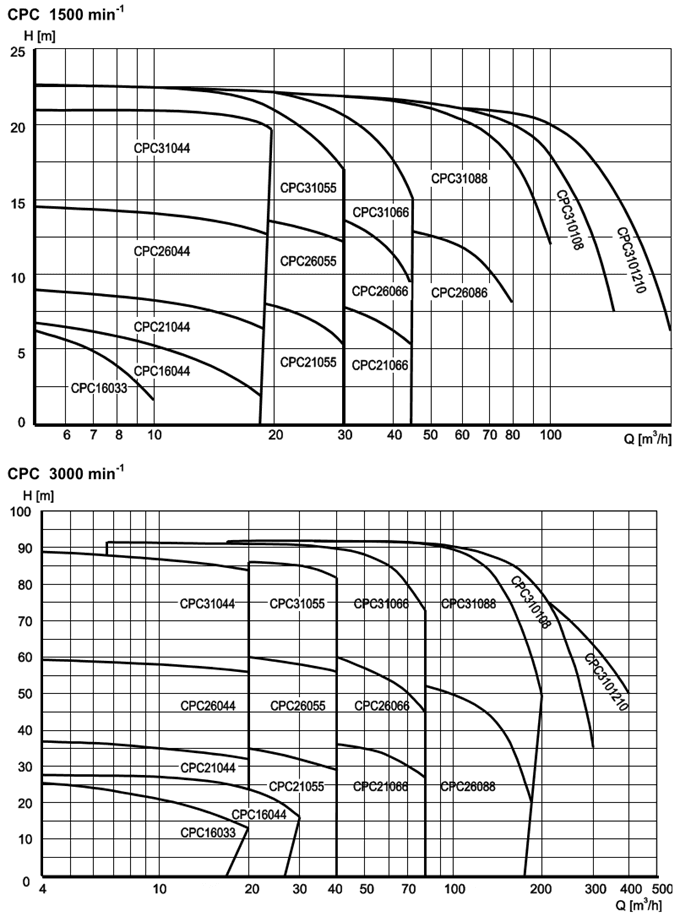

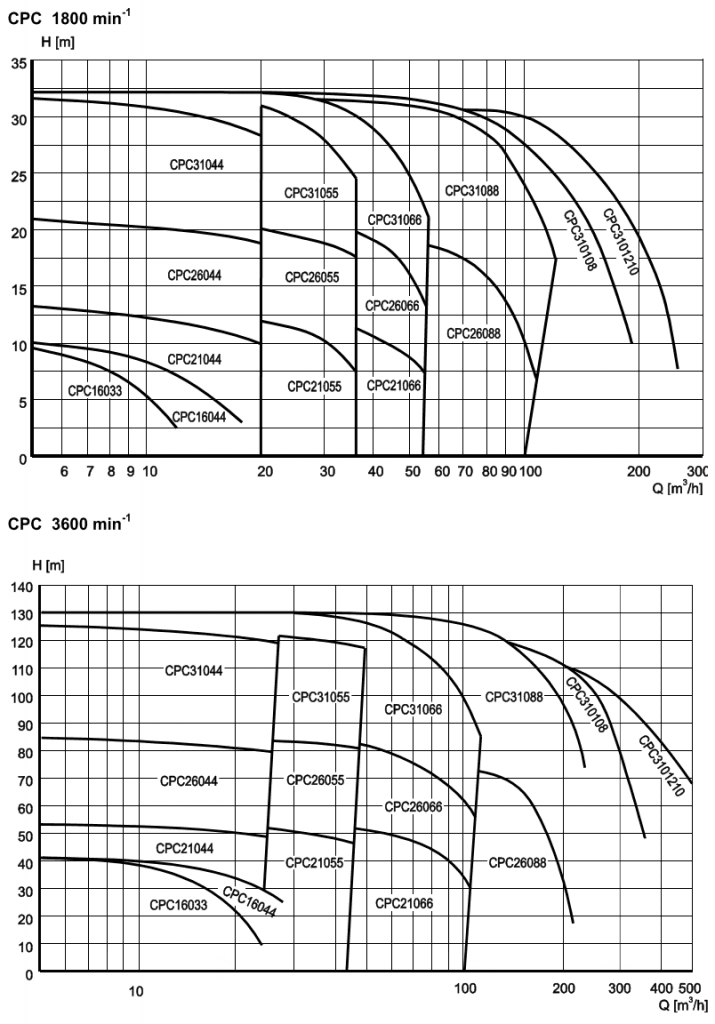

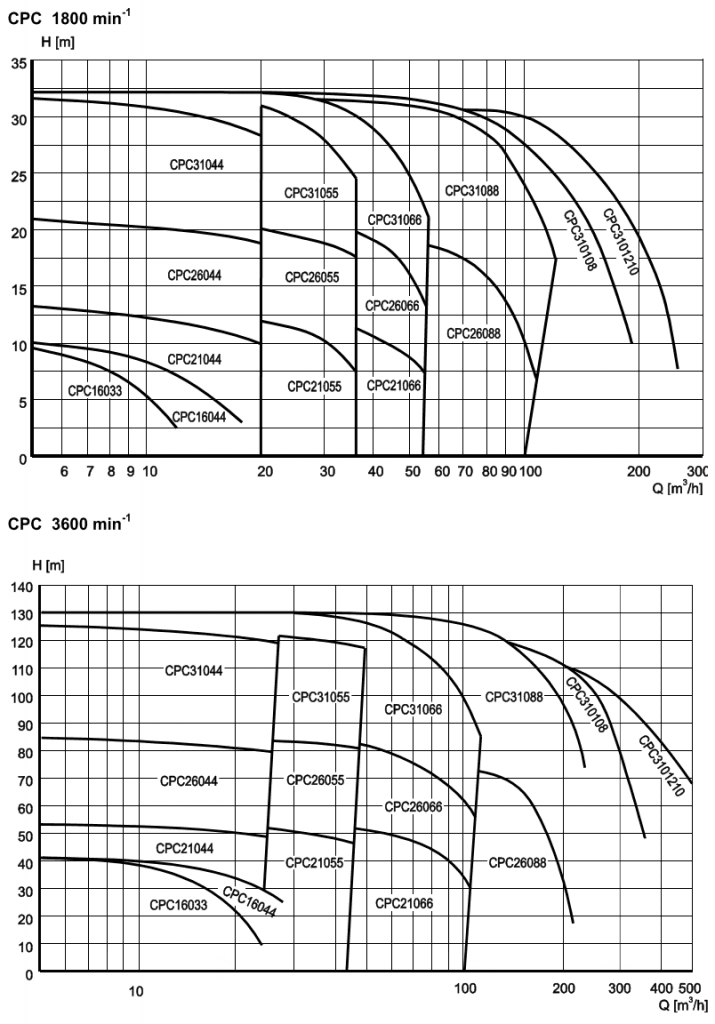

| Maximum Capacity | 500 m³/hr |

| Maximum Pressure | Up to 40 Bar (CPC-HD) |

| Maximum Viscosity | 500 cPs |

| Maximum Temperature | Up to 150ºC |

| Maximum Solids Passage | 10 mm |

| Surface Roughness | <0.8 standard, <0.5 upon request |

| Materials | EHEDG compliant, stainless steel AISI 316L, Hastelloy C22 or AISI 316L Mo Ni |

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

01928 333 400<br> [email protected]<br> [email protected]<br>

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Pump in need of repair? Call TS Pumps today on 01928 333 400

Pump in need of repair? Call TS Pumps today on 01928 333 400

Mon – Thurs 08:30 – 17:00 Friday 08:30 – 16:30

TS Pumps, 10 Cormorant Drive, Runcorn, Cheshire, WA7 4UD