The CTM Magnetically Driven Centrifugal Pump range from Tapflo is ideal for handling low and normal viscous liquids. The sealless design feature of a magnetic drive pump ensures it is airtight, minimising the risk of fluid and vapour leakage from the pump.

| Industry | Example of application |

| Chemical stockists | Transfer of various chemicals from storage tanks to smaller containers |

| Surface treatment | Transfer, filtering and circulation of surface treatment baths |

| Food and beverage | Pumping of CIP detergent used for cleaning of pipes and other food process equipment |

| Water treatment | Dosing of acids and alkalis used as cleaning chemicals in Nanofiltration |

| Chemical manufacture | Pumping of chemicals in industrial detergent equipment |

| Demineralizing | Demi-water circulation and transfer in many industrial applications |

| Photo processing | Transfer of photo develop chemicals and inclusion in processing machines |

| Liquid crystal manufacture | Pumping of concentrated acids and alkalis |

| Casing & Isolation Shell | PP-GF (30%) or PVDF |

| Impeller | PP or PVDF |

| Lantern (Not Wetted) | PP-GF (30%) |

| Static Bushings | Ceramic (Std.) or SiC |

| Rotating Bushings | PTFE-Graphite (Std.) or SiC |

| O-Rings | FKM, EPDM, FFKM, FEP / Silicon |

| Magnets | NdFeB |

| Motor | IEC standard, 3×400 VAC (other on request), 2900 rpm, IP55, B34 frame, IE3 |

| Pressure Ratings | CTM20: PP pumps: PN4 at 20°C, PN2 at 70°C PVDF pumps: PN4 at 20°C, PN2 at 80°C CTM25, CTM32, CTM40 and CTM50: PP pumps: PN6 at 20°C; PN2 at 70°C PVDF pumps: PN6 at 20°C; PN2 at 90°C |

| Temperature Ranges | PP Pumps: 0-70ºC PVDF Pumps: 0-80ºC (CTM 20) / 0-90ºC (CTM25 – 50) |

| Kinematic Viscosity | 200 cSt (max) |

| Dynamic Viscosity | 10 cP (max) |

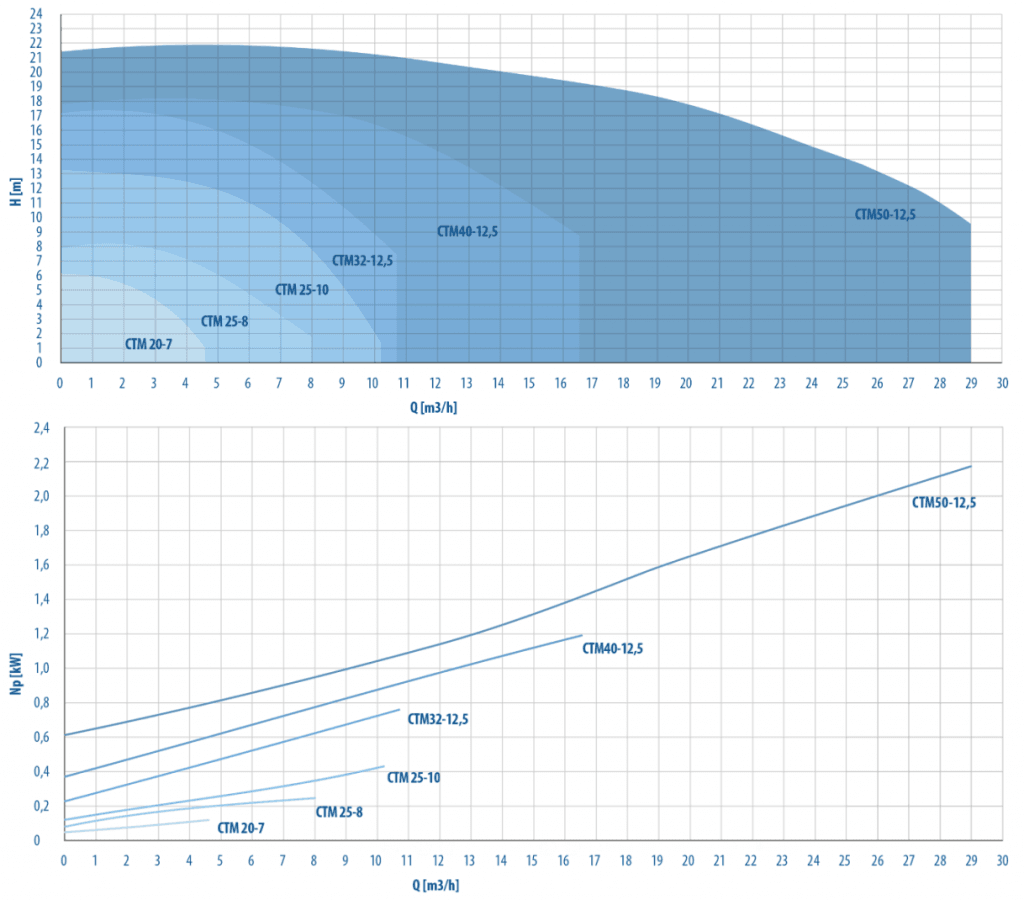

Tapflo’s Mag Drive Centrifugal Pump range is suitable for almost any application due to the wide flow and pressure ranges that these pumps can achieve.

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

01928 333 400<br> [email protected]<br> [email protected]<br>

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Pump in need of repair? Call TS Pumps today on 01928 333 400

Pump in need of repair? Call TS Pumps today on 01928 333 400

Mon – Thurs 08:30 – 17:00 Friday 08:30 – 16:30

TS Pumps, 10 Cormorant Drive, Runcorn, Cheshire, WA7 4UD