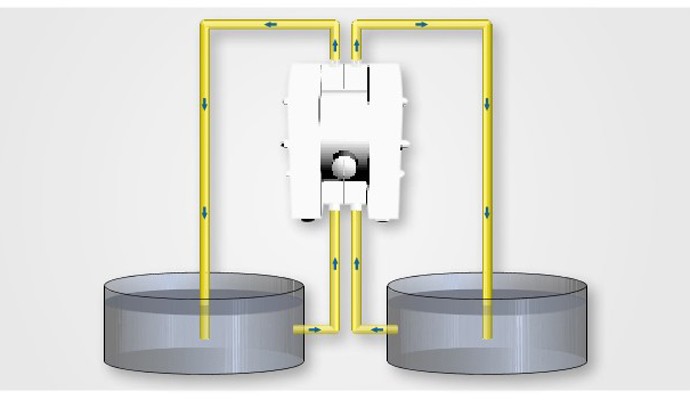

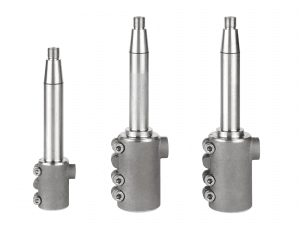

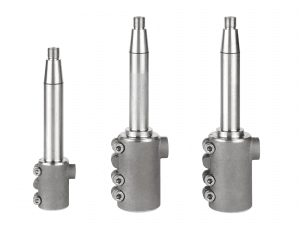

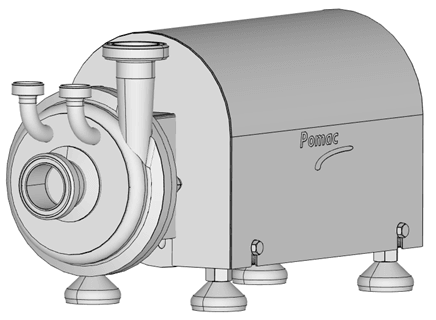

The SP-LR Sanitary Self-Priming Liquid Ring Pump is fully compliant with all relevant standards to be used for hygienic and sanitary applications. It is ideal for food, chemical and pharmaceutical industries that are pumping fluids that contain air or gas.

| Technical Information | |

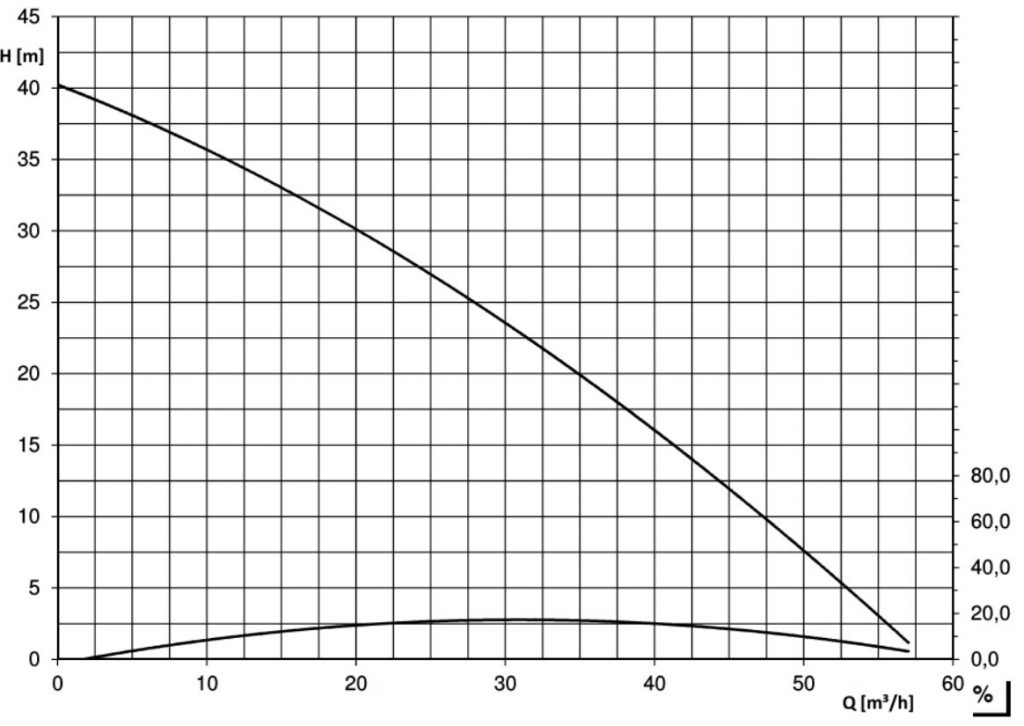

| Maximum Capacity | 60 m³/hr |

| Maximum Viscosity | Up to 500 cPs |

| Maximum Pressure | Up to 4 Bar |

| Maximum Temperature | Up to 140 ºC |

| Maximum Suction Lift | 6-8m |

| Surface Roughness | <0.8 as standard, <0.5 upon request |

| Materials | Cast Stainless Steel AISI 316L, on request can be delivered in Supra SS 316L and Hastelloy C22 |

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

01928 333 400<br> [email protected]<br> [email protected]<br>

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Pump in need of repair? Call TS Pumps today on 01928 333 400

Pump in need of repair? Call TS Pumps today on 01928 333 400

Mon – Thurs 08:30 – 17:00 Friday 08:30 – 16:30

TS Pumps, 10 Cormorant Drive, Runcorn, Cheshire, WA7 4UD