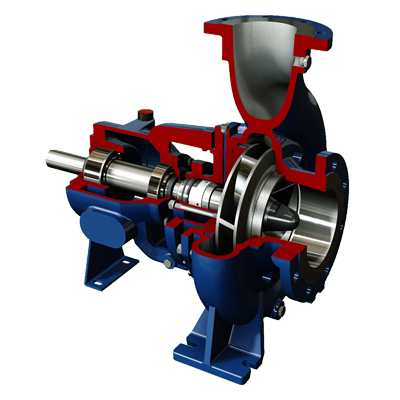

Our highly reliable and robust Salvatore Robuschi Process Pump includes the RD, RG, RB and RC series’. The RD and RG series’ are manufactured from Stainless STEEL 316 as standard, although others are available. The RB and RC series’ are usually manufactured from Cast Iron or Stainless Steel and are commonly used for Wastewater applications where chemical resistance is not needed.

RD and RG models

RD and RG models both conform with ISO 2858 Chemical and ISO 5199 Mechanical specifications. These models are available in 35 different pump sizes, which means they can be applied to a range of industrial applications. These include pumping liquids with aggressive chemicals, high temperatures, high viscosities, high specific gravities or suspended solids.

RC model

The RC model can carry out soft pumping applications containing solids. The pump allows fluid to pass through the pump without it coming into direct contact with the impeller, which avoids damage to large solids within liquids such as olives, peas, beans and seeds.

The RC model can also pump fluids that are composed of 50% concentration of trapped gas

Free passage of large solids: The recessed impeller ensures the passage of the solids and filamentous materials equal to 90% of the delivery port. Long and filamentous solids pass through the pump without clogging or causing damage.

Resistance to wear: Higher abrasion resistance is achieved as the pump casing has been designed to pump liquids together with suspended solids even if abrasive. Surface continuity avoids the presence of clogging and all wearing points have been properly shaped.

One casing cover fits 14 different sealing systems: Only 1 Casing Cover is used for every size of the pump and it can fit every seal type, brand and seal arrangement! The Seal Chamber, which is cylindrical, has dimensions bigger than those suggested by ISO 5199 Norms to grant the best circulation of fluid. Different seal types can be used using limited components, so it is always possible to change from one execution to another. For example from a Single Mechanical Seal to a Double, Packed Gland or Cartridge, by just replacing a few components. As a result, it is easy to modify the pump for a new plant or process requirement in a fast and cost-effective manner. Furthermore, this modular system allows limited stockholding of spares to cover the whole pump range.

RD & RG Centrifugal Pump Features

- Modularity: 3 Bearing Housing & Shaft Groups covering 35 different pump sizes.

- Efficiency: Investment Cast Impellers for high hydraulic efficiencies, open impellers have efficiencies similar to closed impellers.

- Flexibility: 2 Impeller types can be installed in the same casing & 14 different sealing systems can be fitted into the same casing cover.

- Uses Closed Impellers for clean fluids, open impellers for non-abrasive solids, liquids with dissolved gases and critical suction conditions.

RC CENTRIFUGAL PUMP RANGE:

Free passage of large solids: The recessed impeller ensures the passage of the solids and filamentous materials equal to 90% of the delivery port. Long and filamentous solids pass through the pump without clogging or causing damage.

Resistance to wear: Higher abrasion resistance is achieved as the pump casing has been designed to pump liquids together with suspended solids even if abrasive. Surface continuity avoids the presence of clogging and all wearing points have been properly shaped.

One casing cover fits 14 different sealing systems: Only 1 Casing Cover is used for every size of the pump and it can fit every seal type, brand and seal arrangement! The Seal Chamber, which is cylindrical, has dimensions bigger than those suggested by ISO 5199 Norms to grant the best circulation of fluid. Different seal types can be used using limited components, so it is always possible to change from one execution to another. For example from a Single Mechanical Seal to a Double, Packed Gland or Cartridge, by just replacing a few components. As a result, it is easy to modify the pump for a new plant or process requirement in a fast and cost-effective manner. Furthermore, this modular system allows limited stockholding of spares to cover the whole pump range.

Typical applications of the RC Centrifugal Pump Range:

- Food Industry: To transfer liquids with suspended solids such as fruits & vegetables, sludges, stones, grass etc…

- Water Treatment Industry: To transfer liquids with suspended solids and filamentous fluids such as biological sludge, flocculated sludge, clarifier waste.

- Chemical Industry: For crystallizers, transfer, washing and solids or high viscosity substance recovery

- Textile & Tanning Industry: For chemical baths with suspended solids and filamentous fluids.

Technical Information

|

| Model |

RD |

RG |

RB |

RC |

| Closed Impeller |

Semi-Open Impeller |

Channel Impeller |

Vortex Impeller |

| Maximum Flow |

500 m³/hr |

300 m³/hr |

2400 m³/hr |

800 m³/hr |

| Maximum Head |

140m |

95m |

70m |

60m |

| Maximum Temperature |

220ºC |

220ºC |

220ºC |

180ºC |

| Materials |

AISI 316 |

AISI 316 |

C.I. GJL250,

AISI 316 |

C.I. GJL250,

AISI 316 |

If you have further questions, our Pump Specialists will have the answer.

Please don't hesitate to get in touch:

01928 333 400

[email protected]