The HDPE & PTFE Air Operated Double Diaphragm Pump is machined from solid block HDPE and PTFE meaning they are suitable for handling a range of liquids including viscous, chemically aggressive or those containing abrasive solids. This design also means that the Diaphragm Pumps feature approximately 70% fewer parts than other AOD Pumps on the market.

| Pump Size | |||||||

| Data | 9 | 20 | 50 | 100 | 200 | 400 | 800 |

| Pump housing and all wetted | PE or PTFE | ||||||

| Centre block (not wetted) | PP | ||||||

| Diaphragms | PTFE, FKM | PTFE, PTFE 1705B, EPDM or NBR | |||||

| Valve Balls | – | – | PTFE, EPDM, NBR, AISI 316L***, PU, Ceramic*** | ||||

| Rod Valves (TR9 and TR20) | PTFE | – | – | – | – | – | |

| Air Valve | Brass (standard), stainless steel AISI 316L, PET with NBR (standard), EPDM or FKM O-Rings | ||||||

| O-Rings (wetted) | FEP/FKM (standard on pumps with PTFE diaphragms), EPDM, NBR or FKM | ||||||

| Housing Pin Screws | Stainless steel AISI 316L | ||||||

| Diaphragm Shaft | Stainless steel AISI 316L | ||||||

| Drum Handle (TD pumps) | – | Stainless steel AISI 316L | – | – | – | ||

| Reinforcement Plates (TF pumps) | – | – | Stainless steel AISI 316L | – | |||

| Data | Pump Size | ||||||

| 9 | 20 | 50 | 100 | 200 | 400 | 800 | |

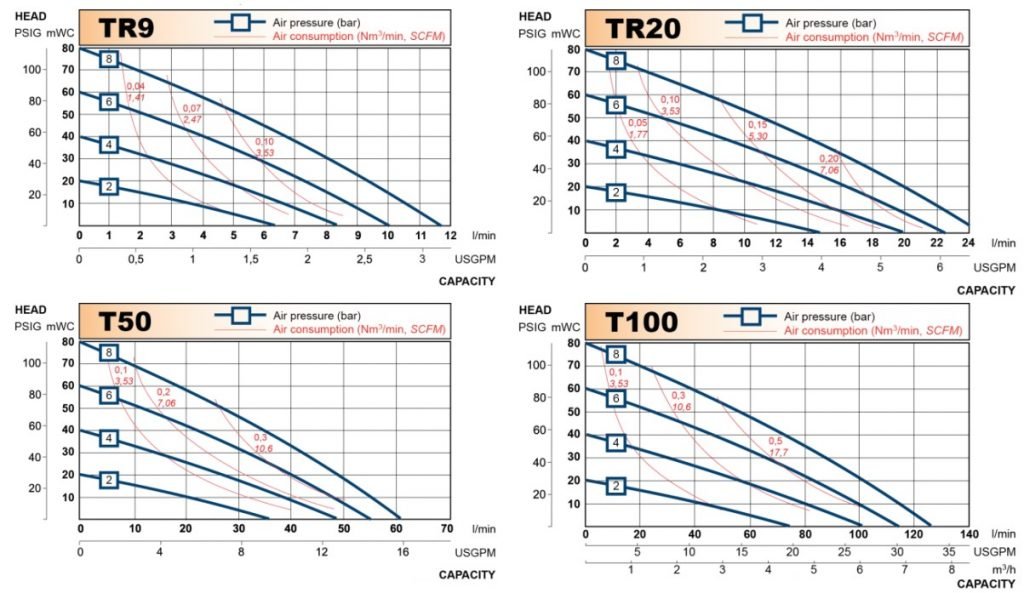

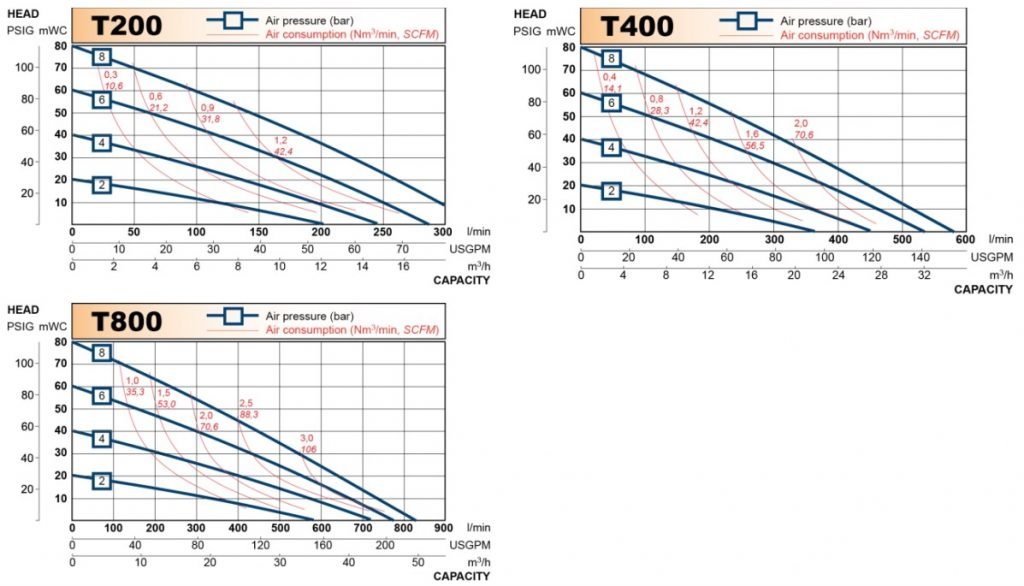

| Max Capacity, l/min (*) | 11 | 24 | 60 | 125 | 330 | 570 | 820 |

| Volume / Stroke, ml (**) | 13 | 50 | 87.5 | 280 | 933 | 2300 | 5125 |

| Max Discharge Pressure, Bar | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Max Air Pressure, Bar | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Max-Dry Suction Lift, m (***) | 1.6 | 2.5 | 2.5 | 3.5 | 4 | 4 | 5 |

| Max Wet Suction Lift, m | 8 | 8 | 9 | 9 | 9 | 9 | 9 |

| Max Permissible ø of Solids, mm | 2 | 3 | 4 | 6 | 10 | 15 | 15 |

| Max Fluid Temp in PE, ºC | 70 | ||||||

| Max Fluid Temp in PTFE, ºC | 100 | ||||||

| Min Fluid Temp, ºC | -20 | ||||||

| Drive Type | Pneumatic |

| Flow Rate | up to 820 l/min |

| Pressure | up to 16 Bar |

| Material | PE & PTFE |

| Self-Priming | Yes |

| Solids Handling | up to 15mm |

| Viscosity | 0-200+ cSt |

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

We pride ourselves on our service and response times, going above and beyond for clients to ensure we provide a long-lasting pump solution. Our pump specialists can help answer any queries and assist with pump projects to help your operation run as smoothly as possible. Get in touch with our sales team today.

01928 333 400<br> [email protected]<br> [email protected]<br>

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Our experts are just a call away: 01928 333 400 Alternatively, fill out the form below and we will be in touch within 24 hours.

Pump in need of repair? Call TS Pumps today on 01928 333 400

Pump in need of repair? Call TS Pumps today on 01928 333 400

Mon – Thurs 08:30 – 17:00 Friday 08:30 – 16:30

TS Pumps, 10 Cormorant Drive, Runcorn, Cheshire, WA7 4UD